除鐵器內(nèi)部采用高矯頑力

RCYB懸掛式永磁除鐵器內(nèi)部采用高矯頑力,高剩磁的特殊永磁體組成的復(fù)合磁系,具有磁場(chǎng)強(qiáng)、壽命長(zhǎng)、運(yùn)行可靠、無(wú)需維護(hù)等特點(diǎn)。與電磁除鐵器的比較無(wú)需電能勵(lì)磁,具有顯著節(jié)能的效果;無(wú)需控制電路,運(yùn)行可靠無(wú)故障;體積小易安裝優(yōu)點(diǎn)。

除鐵器內(nèi)部磁路采用的先進(jìn)的計(jì)算機(jī)輔助設(shè)計(jì),永磁芯八年內(nèi)磁力降低不超過(guò)5%,使用的壽命可達(dá)15年以上。其各項(xiàng)技術(shù)的指標(biāo)均符合JB/T8711-1998標(biāo)準(zhǔn)。 當(dāng)永磁鐵吸附鐵磁物較多對(duì)的時(shí),人工用的非磁性刮板清除或戴手套摘除,適合用于連續(xù)工作,含鐵較少的的場(chǎng)合。

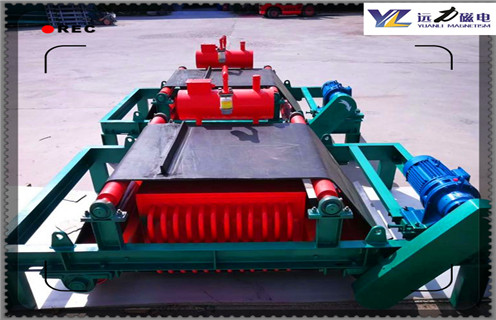

電磁除鐵器

1、主要性能指標(biāo)均達(dá)到或高于JB/T7689-95標(biāo)準(zhǔn)要求

2、磁路采用計(jì)算機(jī)的模擬設(shè)計(jì)、透磁深度大、磁力強(qiáng)。

3、內(nèi)部采用電工專用的樹(shù)脂澆注、自冷式的全密封結(jié)構(gòu)、防塵、防雨、耐腐蝕。

4、波翅型散熱片、使散熱的面積大大的增加、有效控制了溫升。

5、可有效的吸除混雜在非磁性物料中0.1-35公斤的的鐵磁性物質(zhì)。